Navi Mumbai, Maharashtra, India, 410209

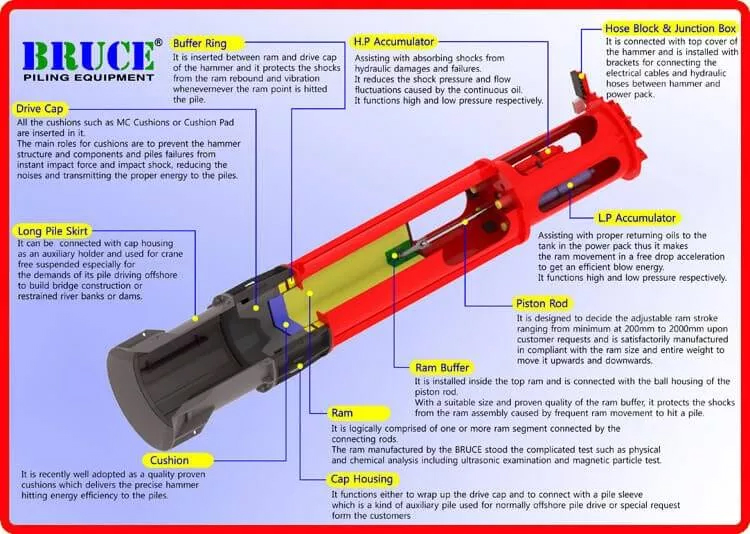

Hydraulic Impact Hammers

Bruce is one of the oldest manufacturers of Hydraulic Impact Hammers.

“BRUCE” stands for Better Result Using this Construction Equipment

ELECTRIC REMOTE CONTROL SYSTEM FOR ADJUSTING IMPACT ENERGY

with Bruce hammer remote control system, user can control piling and failure check in piling Rig cabin or long distance of piling area. Abnormalities in each function are monitored on LED with high brightness signal so that diagnosis and remedy can be done quickly.

with Bruce hammer remote control system, user can control piling and failure check in piling Rig cabin or long distance of piling area. Abnormalities in each function are monitored on LED with high brightness signal so that diagnosis and remedy can be done quickly.

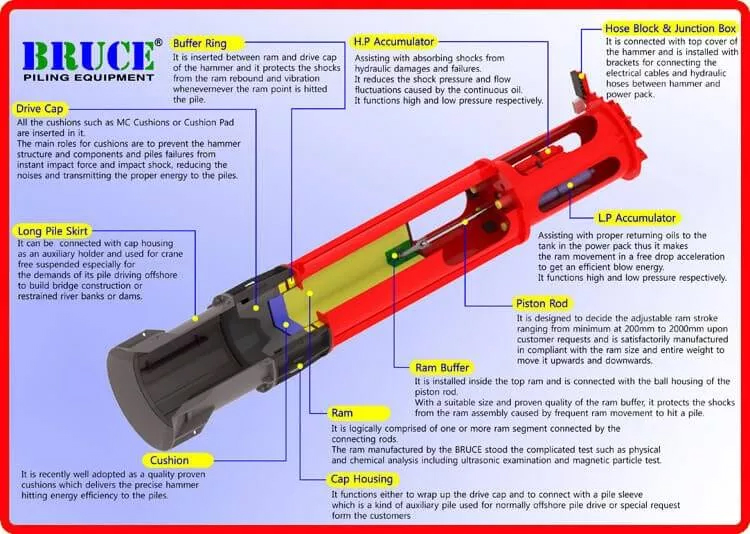

PROMINENT ENERGY TRANSFERRING RATE

with the help of efficient design of hammer body and the cushion arrangement, impact energy from ram drop can be transferred to pile head with lower energy loss. That means the job efficiency can be maximized.

with the help of efficient design of hammer body and the cushion arrangement, impact energy from ram drop can be transferred to pile head with lower energy loss. That means the job efficiency can be maximized.

with the help of efficient design of hammer body and the cushion arrangement, impact energy from ram drop can be transferred to pile head with lower energy loss. That means the job efficiency can be maximized.

with the help of efficient design of hammer body and the cushion arrangement, impact energy from ram drop can be transferred to pile head with lower energy loss. That means the job efficiency can be maximized.

HIGH ENERGY EFFICIENCY & ENERGY TRANSFERRING EFFICIENCY

Compensation of energy drop efficiency during ram drop is functioning by equipped accumulator back charging system to the cylinder.

Compensation of energy drop efficiency during ram drop is functioning by equipped accumulator back charging system to the cylinder.

Compensation of energy drop efficiency during ram drop is functioning by equipped accumulator back charging system to the cylinder.

Compensation of energy drop efficiency during ram drop is functioning by equipped accumulator back charging system to the cylinder.

LONGER LIFE TIME OF CUSHION PARTS INCLUDING BUFFER-RINGS

The well-built structure of hammer cap housing and optimum choice of cushion material ensure longer term use of cushion parts. Therefore customers can achieve the economical operation with lower running cost.

The well-built structure of hammer cap housing and optimum choice of cushion material ensure longer term use of cushion parts. Therefore customers can achieve the economical operation with lower running cost.

The well-built structure of hammer cap housing and optimum choice of cushion material ensure longer term use of cushion parts. Therefore customers can achieve the economical operation with lower running cost.

The well-built structure of hammer cap housing and optimum choice of cushion material ensure longer term use of cushion parts. Therefore customers can achieve the economical operation with lower running cost.

IMPROVED STABILITY AT RAM MOVEMENT

The elaborate design of ram parts and its housing enables the ram to travel minimizing the shock on whole hammer structure and cylinder parts as well. This fact gives improved stability of hammer operation.

The elaborate design of ram parts and its housing enables the ram to travel minimizing the shock on whole hammer structure and cylinder parts as well. This fact gives improved stability of hammer operation.

The elaborate design of ram parts and its housing enables the ram to travel minimizing the shock on whole hammer structure and cylinder parts as well. This fact gives improved stability of hammer operation.

The elaborate design of ram parts and its housing enables the ram to travel minimizing the shock on whole hammer structure and cylinder parts as well. This fact gives improved stability of hammer operation.

LONG-TERM RELIABILITY

Bruce hydraulic hammers are designed and manufactured for long life service with minimal downtime. For the purpose, accurate and precise workmanship are adopted to electric and hydraulic system ensuring low downtime on both systems and promoted endurance with hoses, cables, couplings and other related parts.

Bruce hydraulic hammers are designed and manufactured for long life service with minimal downtime. For the purpose, accurate and precise workmanship are adopted to electric and hydraulic system ensuring low downtime on both systems and promoted endurance with hoses, cables, couplings and other related parts.

Bruce hydraulic hammers are designed and manufactured for long life service with minimal downtime. For the purpose, accurate and precise workmanship are adopted to electric and hydraulic system ensuring low downtime on both systems and promoted endurance with hoses, cables, couplings and other related parts.

Bruce hydraulic hammers are designed and manufactured for long life service with minimal downtime. For the purpose, accurate and precise workmanship are adopted to electric and hydraulic system ensuring low downtime on both systems and promoted endurance with hoses, cables, couplings and other related parts.

VERSATILITY AND CONTROLABILITY

Bruce hammer can drive all types of piles on leader or crane suspension and can accept drive cap inserts for most types and sizes of piles. Bruce hammer also controls the stroke precisely to match hammer energy helping prevent pile damage and pile runaway.

Bruce hammer can drive all types of piles on leader or crane suspension and can accept drive cap inserts for most types and sizes of piles. Bruce hammer also controls the stroke precisely to match hammer energy helping prevent pile damage and pile runaway.

Bruce hammer can drive all types of piles on leader or crane suspension and can accept drive cap inserts for most types and sizes of piles. Bruce hammer also controls the stroke precisely to match hammer energy helping prevent pile damage and pile runaway.

Bruce hammer can drive all types of piles on leader or crane suspension and can accept drive cap inserts for most types and sizes of piles. Bruce hammer also controls the stroke precisely to match hammer energy helping prevent pile damage and pile runaway.

VARIOUS HAMMER MOUNTING TYPE

Fixed Leader Type (Round Shape and Square Type), Crane Suspended Type, Offshore Leader Type, U-Type Leads and others can be adaptable.

Fixed Leader Type (Round Shape and Square Type), Crane Suspended Type, Offshore Leader Type, U-Type Leads and others can be adaptable.

Fixed Leader Type (Round Shape and Square Type), Crane Suspended Type, Offshore Leader Type, U-Type Leads and others can be adaptable.

Fixed Leader Type (Round Shape and Square Type), Crane Suspended Type, Offshore Leader Type, U-Type Leads and others can be adaptable.

ENVIRONMENTALY FRIENDLY CONCERN

Bio-degradable hydraulic oil and low emission engine are provided concerning for earth environmental clean.

Bio-degradable hydraulic oil and low emission engine are provided concerning for earth environmental clean.

Bio-degradable hydraulic oil and low emission engine are provided concerning for earth environmental clean.

Bio-degradable hydraulic oil and low emission engine are provided concerning for earth environmental clean.

IMPACT ENERGY MONITORING SYSTEM (IEA SYSTEM) – OPTIONAL

To meet the demand for precise piling nowadays, Bruce hammer provides energy monitoring system as an optional kit, which enables continuous record of each blow energy on real time basis. Hard print and PC link are available for recording and further analysis.

To meet the demand for precise piling nowadays, Bruce hammer provides energy monitoring system as an optional kit, which enables continuous record of each blow energy on real time basis. Hard print and PC link are available for recording and further analysis.

To meet the demand for precise piling nowadays, Bruce hammer provides energy monitoring system as an optional kit, which enables continuous record of each blow energy on real time basis. Hard print and PC link are available for recording and further analysis.

To meet the demand for precise piling nowadays, Bruce hammer provides energy monitoring system as an optional kit, which enables continuous record of each blow energy on real time basis. Hard print and PC link are available for recording and further analysis.

VARIOUS KIND OF PILE DRIVING POSSIBILITY

Concrete pile (round shape, square shape and octagonal shape), steel casing pile, H-Beam, sheet pile driving is most frequent pile driving way with Bruce hammer.

Concrete pile (round shape, square shape and octagonal shape), steel casing pile, H-Beam, sheet pile driving is most frequent pile driving way with Bruce hammer.

Concrete pile (round shape, square shape and octagonal shape), steel casing pile, H-Beam, sheet pile driving is most frequent pile driving way with Bruce hammer.

Concrete pile (round shape, square shape and octagonal shape), steel casing pile, H-Beam, sheet pile driving is most frequent pile driving way with Bruce hammer.

VISIBLE RAM HEIGHT MOVEMENT

Ram drop height indicator on the side of the hammer is standard equipped with height marking so that operator can see ram drop height easily during pile driving and can adjust ram height stroke during pile driving through remote control box provided.

Ram drop height indicator on the side of the hammer is standard equipped with height marking so that operator can see ram drop height easily during pile driving and can adjust ram height stroke during pile driving through remote control box provided.

Ram drop height indicator on the side of the hammer is standard equipped with height marking so that operator can see ram drop height easily during pile driving and can adjust ram height stroke during pile driving through remote control box provided.

Ram drop height indicator on the side of the hammer is standard equipped with height marking so that operator can see ram drop height easily during pile driving and can adjust ram height stroke during pile driving through remote control box provided.

HIGH BLOW RATE & PRECISE RAM STROKE MOVEMENT ABILITY

High blow rate is effective to fast pile driving and Bruce remote control system is functioning and controlling stable ram stroke and accuracy pile driving works which is very important without failure of pile driving due to sudden unstable ram height movement. In case of soft driving condition, small pitching pile driving is controlled so that preventing from sudden pile drop to the ground thus suspended crane or piling rig is safe.

High blow rate is effective to fast pile driving and Bruce remote control system is functioning and controlling stable ram stroke and accuracy pile driving works which is very important without failure of pile driving due to sudden unstable ram height movement. In case of soft driving condition, small pitching pile driving is controlled so that preventing from sudden pile drop to the ground thus suspended crane or piling rig is safe.

High blow rate is effective to fast pile driving and Bruce remote control system is functioning and controlling stable ram stroke and accuracy pile driving works which is very important without failure of pile driving due to sudden unstable ram height movement. In case of soft driving condition, small pitching pile driving is controlled so that preventing from sudden pile drop to the ground thus suspended crane or piling rig is safe.

High blow rate is effective to fast pile driving and Bruce remote control system is functioning and controlling stable ram stroke and accuracy pile driving works which is very important without failure of pile driving due to sudden unstable ram height movement. In case of soft driving condition, small pitching pile driving is controlled so that preventing from sudden pile drop to the ground thus suspended crane or piling rig is safe.

NEW CONCEPTUAL DESIGN OF A SILENCE CAP HOUSING & KIT - OPTIONAL

We put a new conceptual design of a Silence Cap Housing instead of an existing cap housing on the Bruce hammers can be equipped to reduce the noise emissions considerably. There are sound-absorbing materials which called Noise Insulation in it and it surrounds the Drive Cap to make less noise occurrence from a hard hit to obtain a better result, a piece of MC 904 cushion is used as a cushion material.

We put a new conceptual design of a Silence Cap Housing instead of an existing cap housing on the Bruce hammers can be equipped to reduce the noise emissions considerably. There are sound-absorbing materials which called Noise Insulation in it and it surrounds the Drive Cap to make less noise occurrence from a hard hit to obtain a better result, a piece of MC 904 cushion is used as a cushion material.

We put a new conceptual design of a Silence Cap Housing instead of an existing cap housing on the Bruce hammers can be equipped to reduce the noise emissions considerably. There are sound-absorbing materials which called Noise Insulation in it and it surrounds the Drive Cap to make less noise occurrence from a hard hit to obtain a better result, a piece of MC 904 cushion is used as a cushion material.

We put a new conceptual design of a Silence Cap Housing instead of an existing cap housing on the Bruce hammers can be equipped to reduce the noise emissions considerably. There are sound-absorbing materials which called Noise Insulation in it and it surrounds the Drive Cap to make less noise occurrence from a hard hit to obtain a better result, a piece of MC 904 cushion is used as a cushion material.